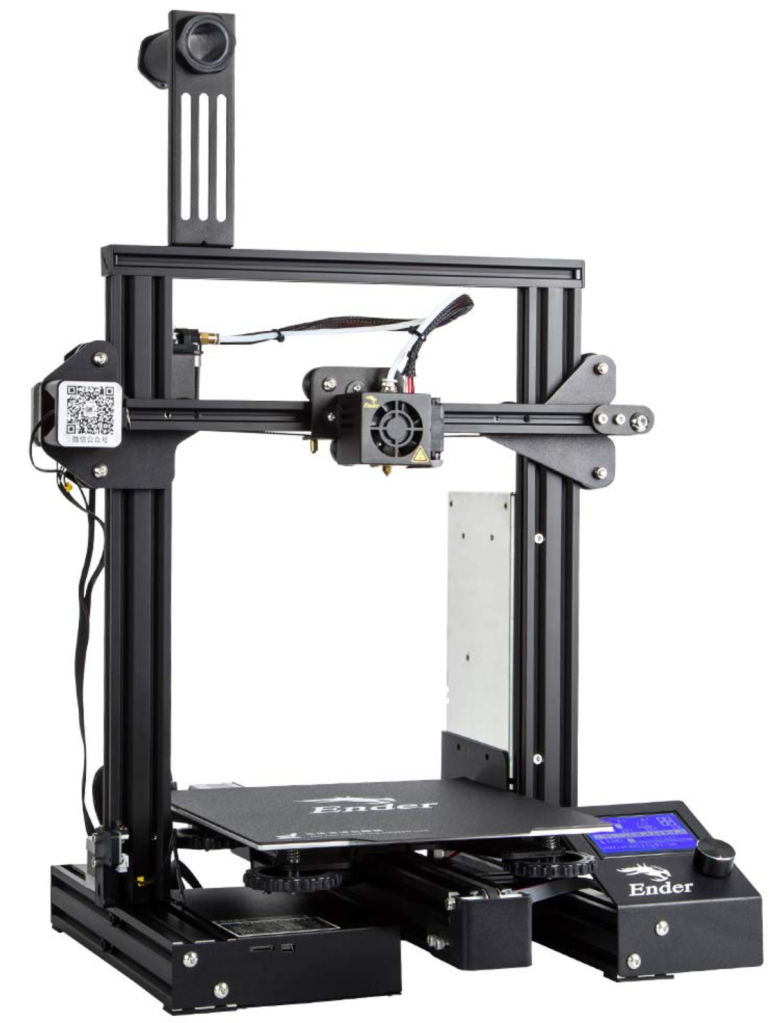

Getting into keyboards in turn led me to give 3D printing a try, because when you do the more DIY keyboard stuff you end up with a lot of things where it’s the easiest or only way to get certain parts, and I didn’t want to bug my roommate to print stuff for me quite that much. There are several kinds of 3D printing (including ceramic, metal, and various kinds of food), but if you’re a hobbyist and don’t have thousands of dollars to throw around, the two types you can get right now are filament and resin. Resin printing can produce much more detailed prints, but it requires dealing with toxic chemicals, so I went for an entry-level filament printer, specifically an Ender 3 Pro, which cost me a little over $200 or so.

Filament printers (or more properly FDM–“fused deposition modeling”) take in a plastic filament and push it through a heated nozzle that is placed so that motors can precisely move it along the X, Y, and Z axes, building up an object in layers. There are several different types of filament available, but the most common is PLA (polylactic acid), which has a relatively low melting point, produces reasonably durable prints, and is non-toxic. (It’s not edible, but it is food-safe, and gets used to make compostable drinking glasses, albeit compostable via industrial processes.) You can print with for example ABS (a very common, basic plastic frequently used for keycaps), but it creates a burning styrofoam smell and fumes, which is why I’ve never used it. (Better quality keycaps use a plastic called PBT, but it has significantly higher temperature tolerances, which I suspect is why it isn’t used for 3D printing.) Most other materials have other issues with things like adhering to the print bed or adding wear and tear to the printer nozzle.

Resin printing meanwhile uses a vat of liquid resin, and it has a device–either an LCD screen or a laser–that uses UV light to harden a layer. It then pulls the print up slightly and repeats the process until the print is done. The ability to print an entire layer at once means that it can potentially be faster than FDM printing. On the other hand you have to wash the finished print in alcohol and cure it in UV light, and you should be wearing protective gloves and have good ventilation for the whole process. The level of detail these printers can produce is exceptional though, and they can do things that FDM printers either can’t manage or struggle with.

3D printing is a time-consuming and finnicky process. If I print something on a paper printer, issues are rare and it only takes a few seconds to spit out a printed page. With 3D printing it’s very easy to end up with a print that takes several hours or even multiple days, and printing failures are to be expected, especially when you’re starting out. I had a lot of failing around as I got the hang of bed leveling and so on.

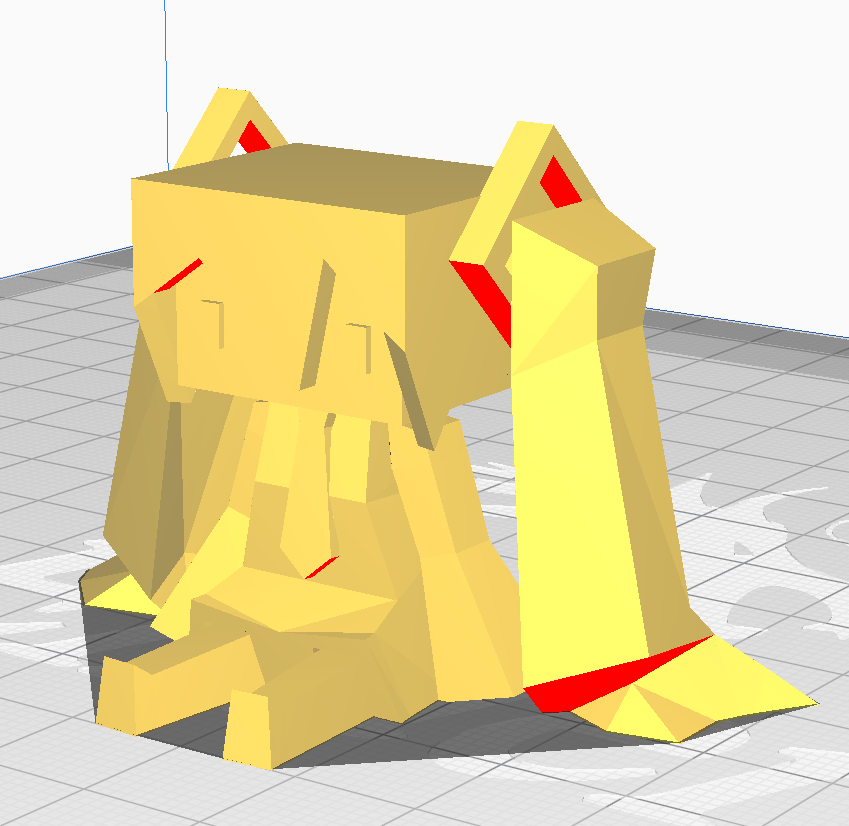

Most 3D printers have you take your 3D model (usually an STL file, though there are some other formats out there) and put it into a “slicing” program that lets you set parameters and convert it into a series of instructions for your particular printer. You can tweak things like the level of precision and the amount of infill (how much of the interior of the object is filled in; at less than 100% it generates a honeycomb pattern to save on filament while maintaining a strong structure), arrange the model(s) on your printing bed, and change the scale. From there you put the converted model onto an SD card, stick that into your printer, and tell it to start. The printer is essentially just following a series of instructions–it doesn’t have sensors to detect issues or anything like that–and more advanced users have found ways to tweak those instructions in interesting ways. One guy set it up so that his printer would print a part, use the side of the printing nozzle assembly to knock the finished part off the printing bed into a container, and repeat.

There’s a massive amount of stuff you can make with a 3D printer, even if you don’t have any clue how to do any 3D modeling. There are a number of sites with free models, the biggest of which is Thingiverse. For any given thing where normally you’d get a plastic item made in China, chances are you can 3D print something. (Food safety is a little tricky because although PLA itself is food safe, the crenellations that 3D printing creates can trap bacteria, so it’s necessary to apply a food safe coating.) That in turn means that 3D printing has exciting possibilities in terms of a more sustainable lifestyles, since it would let us cut down on how much stuff we’re shipping halfway around the world, and it naturally works best with a biodegradable plastic. Of course, the technology needs become more reliable and less technical for the end user before it can gain widespread adoption. Right now it’s more the domain of geeky hobbyists who are willing to put up with the frustrations that come with it.

When I’ve asked people what I should print, more than once I’ve gotten a sarcastic reply that I should print a 3D printer. That’s a very involved project with all the wiring and such involved, but it’s actually something you can do! Hobbyist 3D printing is mostly open-source, plus people just generally like that kind of silliness. There are also quite a few mods for printers that you can 3D print, and in particular I found that adding an extruder knob to my printer made changing filament much easier. There are also a lot of accessories for tech items (for example I printed a stand for my HomePod mini), household items, and figures of pop culture characters.

3D printing has a lot of potential to be of benefit to tabletop gaming. My roommate has a resin printer specifically to supplement his Warhammer 40k armies, and there are tons of models for miniatures, dice towers, board game storage solutions, and so on. People with 3D printers are still enough of an exception that it’s not ready to be the main way a given game gets into people’s hands, but it’s an option that a publisher can put out there if they want (potentially with a greater customizability), as well as a good way to do prototyping.

A thing I realized is that 3D printing is one tool, and just as you can do an entire piece with just a pencil or go on to add other materials, a 3D print can be a starting point, after which you can go on to add things like sanding, painting, coatings, hardware, LEDs and other electronics, etc. That lets you overcome a lot of the limitations of 3D printing, adding different colors, capabilities, and so on rather than just sticking with the single-color, layered look of basic 3D printing. Among other things my roommate 3D printed a Blue Spirit mask from Avatar: The Last Airbender, and then finished it with sanding and painting to produce a really excellent cosplay prop.

3D printers that can handle multiple types of filament or outright add coloring are still relatively new and expensive, but given how fast the technology has developed–from bleeding edge tech with limited industrial uses to an open-source technology you can get into at home for a few hundred dollars in about a decade–it’s undoubtedly going to become cheaper and more accessible.

The amount of stuff I want to 3D print has been enough that it’s going to take a good while to work through it all, and lately I’ve been hearing the whine of stepper motors all day most days. It’s not something I’d recommend everyone get into given the expense and frustration it can entail, but it can be relatively cheap, and there’s all kinds of neat stuff you can do with it.